Views: 0 Author: Site Editor Publish Time: 2023-09-13 Origin: Site

In the realm of manufacturing, precision and innovation are paramount. One technology that has revolutionized the way we create and design products, particularly in our company's showcase of expertise, is laser cutting. The significance of laser cutting technology in the manufacturing of our display racks cannot be overstated. It represents the nexus where precision, speed, and versatility converge to bring forth exceptional results.

In this article, we will embark on a journey to explore the pivotal role of laser cutting technology in shaping the future of our display rack manufacturing. We invite you to delve into the world of precision engineering and discover how this cutting-edge technique elevates our products to new heights. Prepare to be intrigued and inspired by the capabilities of laser cutting technology as we unveil the artistry and innovation it brings to the forefront of our craftsmanship.

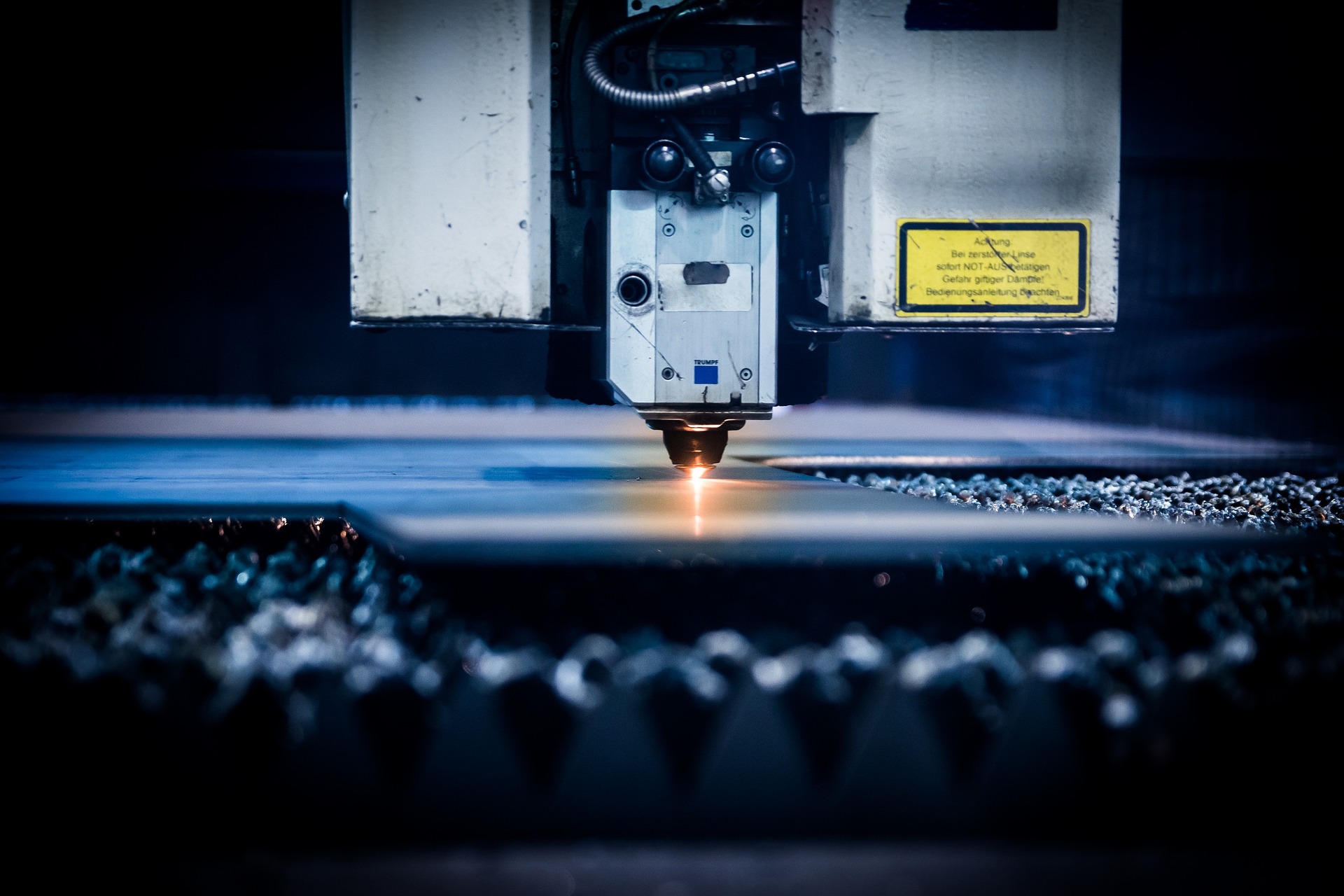

laser cutting

Laser cutting, a pinnacle of modern manufacturing, relies on the power of focused light to create precision cuts with unrivaled speed and accuracy. This advanced process involves the use of a high-powered laser beam, typically generated through the interaction of intense light with a medium, such as a crystal or gas. The resulting laser beam, tightly focused and incredibly intense, is directed onto the material to be cut.

What sets laser cutting apart is its astonishing precision. The laser beam operates with a near-zero width, enabling it to cut intricate shapes, delicate patterns, and fine details with remarkable accuracy. This level of precision is simply unattainable through traditional cutting methods, making laser cutting indispensable for intricate designs and complex geometries.

The speed at which laser cutting operates is equally impressive. The concentrated energy of the laser beam allows it to swiftly slice through materials, minimizing production time and optimizing efficiency. Whether we're working with metal, acrylic, wood, or a variety of other materials, laser cutting consistently delivers rapid results without compromising on quality.

Laser cutting technology offers a marriage of precision and speed that's second to none. It's a process that defines the future of manufacturing, providing the means to craft intricate, high-quality products with efficiency and finesse.

Laser cutting technology is a driving force in the realm of display rack production, enabling the creation of highly customized and unique solutions. Here, we explore the tangible applications of laser cutting and how it transforms the crafting of bespoke display racks.

In the world of retail, where the presentation is paramount, laser cutting's precision and versatility shine. Consider the scenario of a high-end fashion boutique seeking to showcase its latest collection of designer handbags. Laser cutting allows for the creation of tailored display racks that not only securely hold each bag but also accentuate the brand's aesthetic. Intricate patterns and branding elements can be precisely etched or cut into the racks, reinforcing the boutique's identity and creating an immersive shopping experience.

Moreover, the versatility of laser cutting extends to adaptability. In the fast-paced world of retail, where product lines and store layouts frequently change, laser-cut racks offer solutions that can be easily reconfigured. This flexibility caters to evolving needs and ensures that display racks remain versatile assets that can be adjusted to accommodate shifting requirements.

In essence, laser cutting technology's real-world applications in display rack production empower us to create customized solutions that elevate aesthetics, reinforce branding, and enhance functionality. It exemplifies the fusion of precision engineering and artistic design, resulting in display racks that are not only functional but also works of craftsmanship tailored to unique needs.

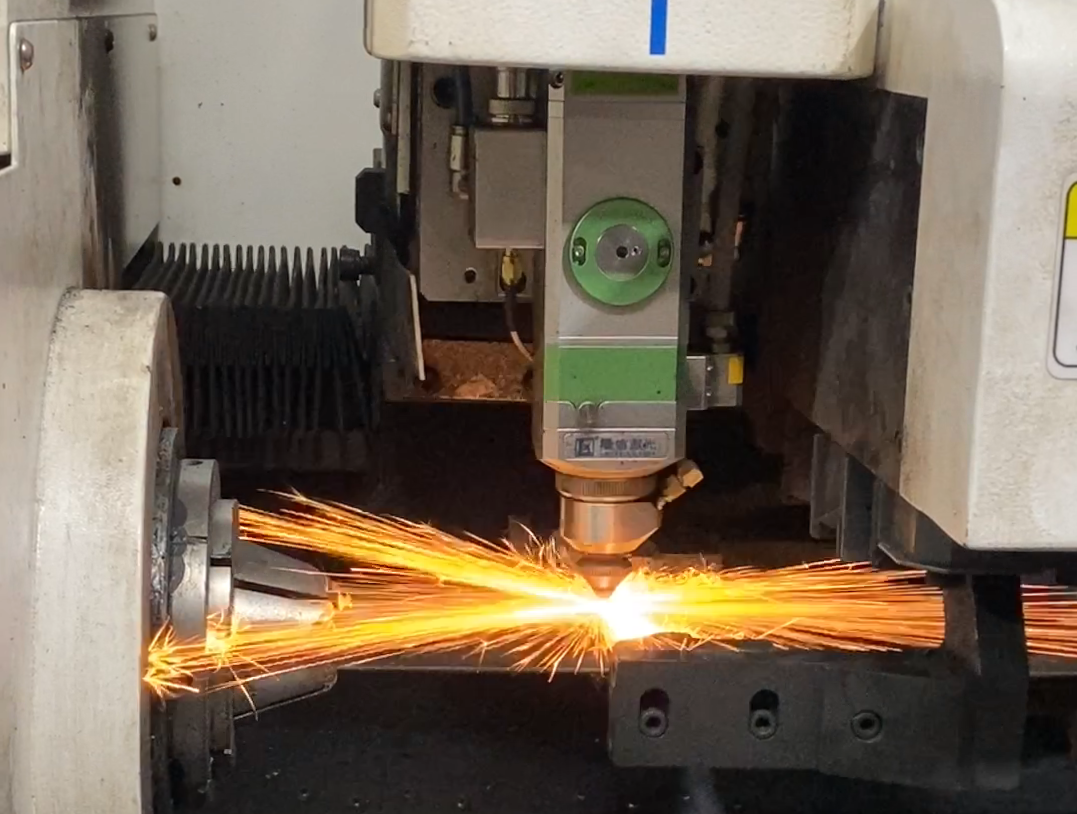

Laser cutting

In the landscape of display rack manufacturing, the adoption of laser cutting technology represents a seismic shift from traditional methods. This transition is driven by significant disparities in efficiency and precision.

Traditional manufacturing techniques often involve processes like manual cutting, which, while tried and tested, are inherently limited in terms of precision. In contrast, laser cutting brings an unparalleled level of accuracy to the table. The focused laser beam operates with minimal width, allowing for intricately detailed cuts and patterns that are simply unattainable through conventional means.

Furthermore, the speed at which laser cutting operates is a game-changer. Traditional manufacturing techniques can be time-consuming, requiring multiple steps and manual labor. In contrast, laser cutting completes tasks with rapidity. Whether it's cutting, engraving, or etching, laser technology performs these operations swiftly and efficiently. This not only accelerates production but also reduces costs associated with labor and time.

In essence, the transition to laser cutting represents a paradigm shift in display rack manufacturing, where precision and efficiency converge. The difference is stark: from the meticulousness of intricate designs to the expeditiousness of production, laser cutting technology elevates display rack creation to an entirely new level.

In the realm of display rack manufacturing, the adoption of laser cutting technology is nothing short of revolutionary. As we conclude our exploration of this pivotal tool, it becomes abundantly clear that laser cutting is the cornerstone of our commitment to precision, efficiency, and customization.

We invite you to join us in celebrating the remarkable capabilities of laser cutting technology and to envision the possibilities it unlocks for your own projects. Together, we can create display racks that not only meet but exceed your expectations—where precision, efficiency, and customization converge to shape the future of presentation.