Views: 162 Author: Site Editor Publish Time: 2024-02-29 Origin: Site

1.Introduction

2.Design principle of bolt-type storage shelf

3.Application scenarios of bolted storage shelves

4.Design and layout

5.The strength of our factory

6.Conclusion

In the realm of warehousing and storage, efficient utilization of space is paramount. Among the arsenal of storage solutions available, boltless shelving stands out for its versatility, durability, and adaptability to various storage needs. This type of shelving system plays a pivotal role in optimizing storage space within warehouses, distribution centers, retail spaces, and other industrial environments. In this article, we delve into the significance of boltless shelving in the warehousing industry, exploring its design principles and diverse application scenarios. From understanding its fundamental design concepts to examining its practical implementations, we aim to provide insights into how boltless shelving enhances storage efficiency and addresses the evolving needs of modern logistics and storage management.

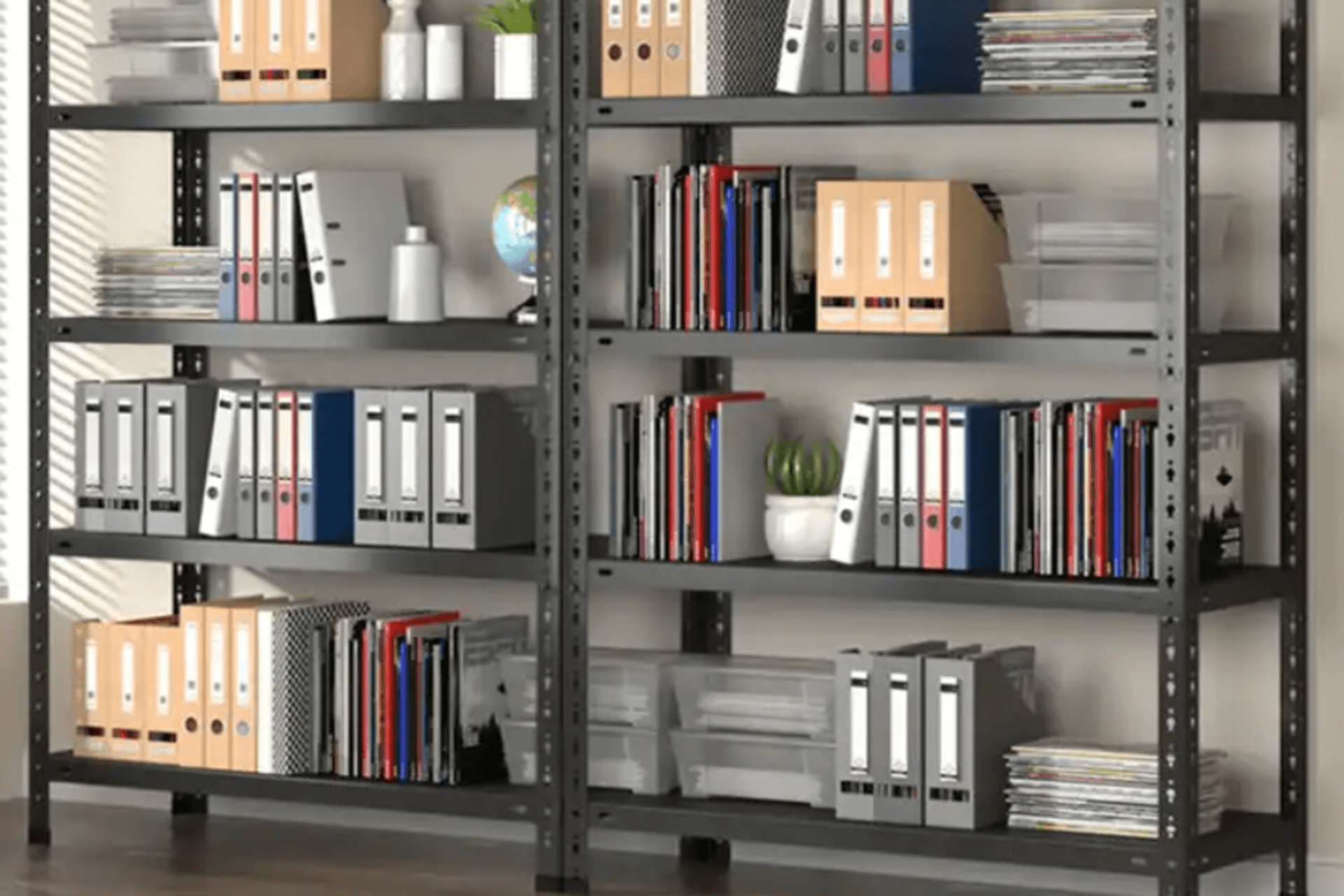

Bolted storage shelves

Boltless shelving, also known as rivet shelving or rivet rack, is a type of storage system characterized by its simple yet robust design. At its core, boltless shelving consists of four primary components: beams, uprights, shelves, and rivets.

The uprights, typically made of heavy-duty steel, serve as the vertical support columns of the shelving system. They are designed with evenly spaced slots or keyhole perforations along their length, providing flexibility for shelf height adjustment. The beams, also constructed from durable steel, are inserted into these slots or perforations to create the horizontal support for the shelves.

Shelves, often made of steel or particle board, rest on the beams and form the horizontal storage surfaces. They come in various sizes and configurations to accommodate different storage needs, from lightweight items to heavy-duty loads.

Rivets play a crucial role in securing the components of the shelving system together. These rivets, typically made of steel or aluminum, are inserted into the uprights and beams to create a sturdy connection without the need for nuts, bolts, or additional hardware. The riveting process is straightforward and requires no specialized tools, making assembly quick and hassle-free.

The structure of boltless shelving is based on the principle of interlocking components, where the uprights, beams, shelves, and rivets fit together seamlessly to create a stable and reliable storage solution. This design eliminates the need for traditional fasteners, such as nuts and bolts, resulting in a more streamlined and efficient assembly process.

The structure and principle of boltless shelving emphasize simplicity, durability, and versatility. By understanding the functionality of each component and how they work together, users can effectively utilize boltless shelving to optimize their storage space and enhance organizational efficiency.

Boltless shelving finds wide-ranging applications across various industries and environments due to its versatility, durability, and ease of assembly. In warehouses, boltless shelving is commonly used for storing a wide range of products, from small parts and components to large boxes and containers. The adjustable shelves make it easy to customize the storage space according to the size and weight of the items being stored. Warehouses often utilize boltless shelving for bulk storage, picking areas, and inventory management due to its ability to maximize vertical space while providing easy access to stored goods.

In supermarkets and retail stores, boltless shelving serves as an essential storage solution for displaying merchandise in an organized and visually appealing manner. The adjustable shelves allow retailers to showcase products of varying sizes and shapes effectively, optimizing the use of available floor space. Boltless shelving is commonly used for displaying items such as groceries, household goods, electronics, and apparel, enabling easy browsing for customers while facilitating efficient restocking and inventory management for store staff.

In manufacturing facilities and factories, boltless shelving plays a crucial role in organizing raw materials, components, and finished products. These shelving units are often installed in production areas, storage rooms, and assembly lines to keep materials organized and easily accessible for production processes. Boltless shelving is particularly valued in manufacturing environments for its strength and durability, capable of withstanding heavy loads and harsh industrial conditions.

Furthermore, boltless shelving is widely utilized in office spaces, garages, workshops, and even residential settings for various storage needs. In offices, boltless shelving is often used for filing documents, storing office supplies, and organizing equipment. In garages and workshops, these shelving units provide a convenient solution for storing tools, equipment, and automotive parts. Additionally, boltless shelving can be found in residential settings as storage solutions for household items, pantry goods, and personal belongings.

The versatile nature of boltless shelving makes it a practical storage solution for a wide range of industries and environments, including warehouses, supermarkets, factories, offices, garages, workshops, and residential spaces. Its adaptability, durability, and ease of assembly make it an ideal choice for optimizing storage space and enhancing organizational efficiency across diverse applications.

When designing boltless shelving systems, several considerations and layout principles should be taken into account to ensure optimal functionality and space utilization. Firstly, it's essential to assess the specific storage needs and requirements of the intended application. Understanding the types of items to be stored, their dimensions, weights, and frequency of access will help determine the shelving configuration and load capacity needed.

Next, considering the available space is crucial for determining the size, quantity, and arrangement of shelving units. Utilizing vertical space efficiently by installing taller shelving units can maximize storage capacity while minimizing the footprint on the floor. Additionally, designing the shelving layout to fit seamlessly into the available space, including corners and irregular areas, can help maximize storage capacity.

In terms of shelving design, opting for adjustable shelves allows for flexibility in accommodating items of various sizes and shapes. Adjustable shelving also facilitates reconfiguration as storage needs change over time. Furthermore, incorporating accessories such as dividers, bins, and labeling systems can enhance organization and accessibility within the shelving units.

When arranging the shelving units, it's essential to prioritize accessibility and ease of navigation. Placing frequently accessed items at eye level or within arm's reach ensures convenient retrieval and restocking, while less frequently accessed items can be placed on higher or lower shelves. Additionally, leaving adequate aisle space between shelving rows facilitates smooth movement and navigation within the storage area.

Considering weight distribution is another crucial aspect of shelving design and layout. Distributing heavier items evenly across the shelves and avoiding overloading individual shelves beyond their weight capacity ensures structural integrity and safety. It's also advisable to place heavier items on lower shelves to lower the center of gravity and minimize the risk of tipping.

Furthermore, maintaining clear labeling and signage within the shelving units aids in identifying and locating stored items efficiently. Clear labeling also contributes to inventory management and stock rotation processes, reducing errors and improving overall operational efficiency.

When designing and laying out boltless shelving systems, it's essential to consider storage needs, available space, shelving design features, accessibility, weight distribution, and organization principles. By incorporating these considerations and practical recommendations, businesses can optimize space utilization, enhance storage efficiency, and improve overall workflow in various storage environments.

Our factory takes pride in its 17 years of experience in manufacturing customized shelving solutions. Over the years, we have honed our expertise and developed a deep understanding of the intricacies involved in crafting high-quality display racks tailored to meet our clients' diverse needs.

One of our key strengths lies in our team of seasoned designers who bring creativity, innovation, and practicality to every project they undertake. With their wealth of experience and keen eye for detail, they collaborate closely with clients to translate their vision into functional and aesthetically pleasing shelving solutions.

At our factory, quality is paramount. We adhere to stringent quality control measures at every stage of the manufacturing process, from sourcing materials to final assembly. By maintaining uncompromising standards, we ensure that each display rack leaving our facility meets the highest quality benchmarks, guaranteeing durability, reliability, and longevity.

Despite our unwavering commitment to quality, we also understand the importance of affordability. We strive to offer competitive pricing without compromising on the quality of our products. Our cost-effective solutions enable clients to maximize their investment while enjoying exceptional value for money.

Additionally, we believe in fostering long-term relationships with our clients by providing comprehensive after-sales support. Our dedicated customer service team is readily available to address any queries, concerns, or issues that may arise post-purchase. We stand behind our products and remain committed to ensuring our clients' satisfaction throughout their shelving journey.

Our factory's extensive experience, talented team of designers, dedication to quality, competitive pricing, and reliable after-sales support collectively underscore our capabilities and commitment to delivering top-notch customized shelving solutions that exceed our clients' expectations.

In summary, bolted storage racks stand out for their crucial role in optimizing space utilization, which is essential across various industries for efficient inventory management and organizational productivity. The ability to customize configurations and adapt layouts to specific needs allows businesses to maximize available space effectively, minimizing wasted areas and improving overall storage capacity. This high level of space efficiency translates into cost savings and operational improvements, making bolted shelving systems indispensable in warehouse, retail, manufacturing, and other storage-intensive environments.

Looking ahead, the future of bolted storage racks appears promising, driven by ongoing advancements in design, materials, and technology. Innovations in modular designs, advanced materials, and integrated automation are expected to further enhance the functionality and versatility of bolted shelving systems. Additionally, as sustainability becomes increasingly important, eco-friendly materials and practices are likely to gain traction in the design and manufacturing processes of bolted storage racks, aligning with the broader trend toward environmentally conscious solutions.

Furthermore, with the rise of e-commerce and the growing demand for efficient warehouse management solutions, bolted storage racks are poised to play an even more significant role in facilitating streamlined operations and supporting the evolving needs of modern businesses. The adaptability and scalability of bolted shelving systems make them well-suited for a wide range of applications, from traditional storage facilities to automated warehouses and beyond. As businesses continue to prioritize space optimization and operational efficiency, the demand for innovative bolted storage solutions is expected to increase, driving further advancements and applications in the field.