Views: 126 Author: Site Editor Publish Time: 2024-03-26 Origin: Site

1.Introduction

2.Overview of cold chain management

3.The role of cold storage display rack

4.Design elements and features

5.Application case analysis

6.Technological innovation and future development

7.Strength analysis of the factory

8.Conclusion

In the food industry, maintaining the quality and safety of perishable products is paramount. This is where cold chain management plays a crucial role. Cold chain management refers to the process of maintaining a consistent temperature throughout the supply chain, from production to consumption, to ensure that perishable goods such as fruits, vegetables, dairy, meat, and seafood remain fresh and safe for consumption. With the increasing demand for fresh and frozen food products globally, effective cold chain management has become indispensable. At the heart of cold chain management lies the efficient storage and display of products in refrigerated environments, and this is where cold storage shelving systems come into play. Cold storage shelving systems serve as essential components of cold chain management, providing organized and optimized storage solutions for perishable goods while preserving their quality and integrity. In this article, we will delve into the significance of cold chain management in the food industry and explore the indispensable role of cold storage shelving systems in ensuring the smooth operation of the cold chain.

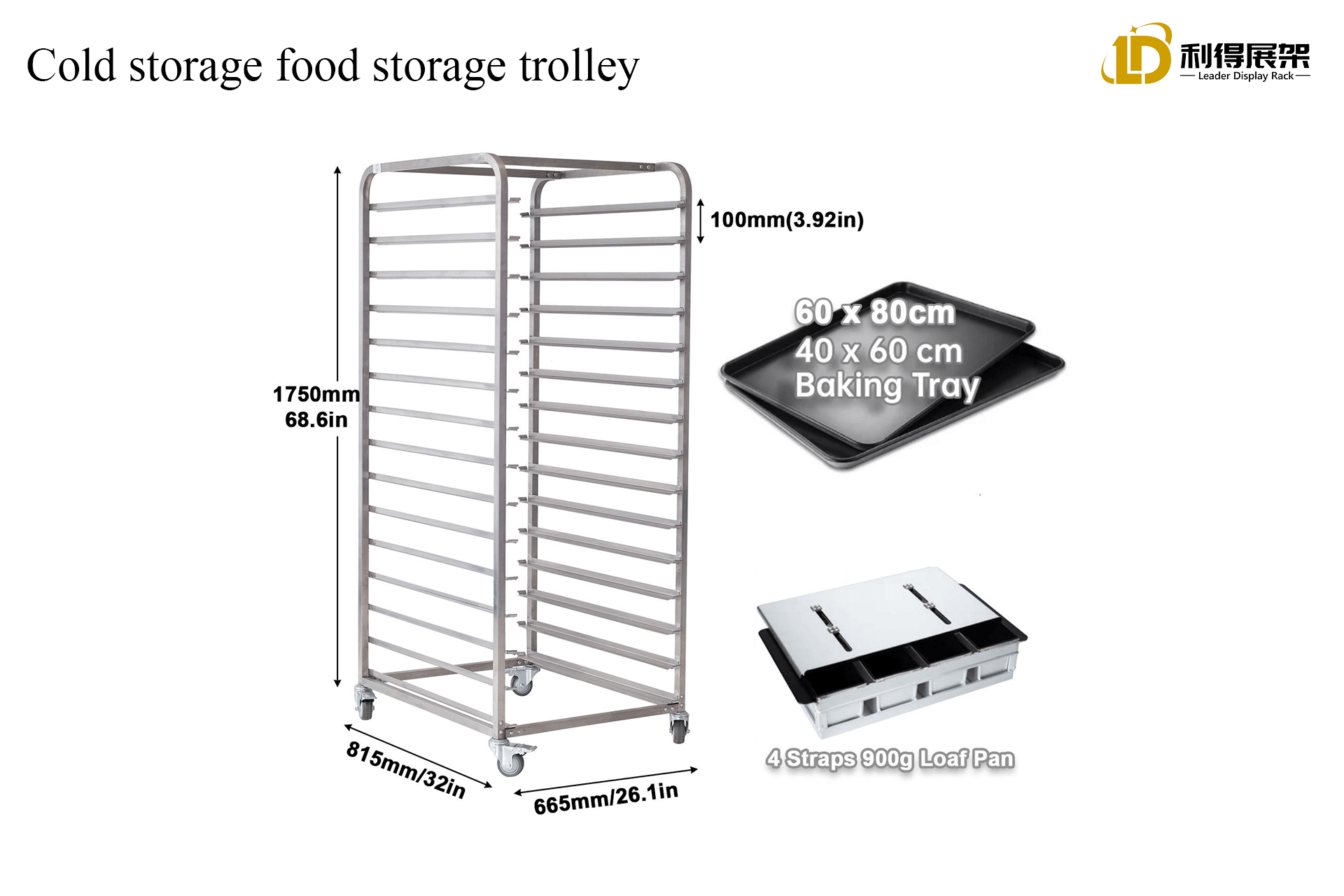

cold storage food sotrage trolley

Cold chain management is a vital process in the food industry, encompassing the careful handling and transportation of perishable goods within a controlled temperature environment throughout the entire supply chain. The primary objective of cold chain management is to maintain the quality, safety, and freshness of perishable products, ensuring that they reach consumers in optimal condition. This involves the systematic monitoring and control of temperature, humidity, and other environmental factors at every stage of the supply chain, from production and storage to distribution and retail.

One of the key roles of cold chain management is to uphold food safety standards. Perishable food items are susceptible to microbial growth, enzymatic reactions, and chemical changes when exposed to improper temperatures. Cold chain management helps prevent the proliferation of harmful pathogens and the occurrence of foodborne illnesses by keeping food products within the safe temperature range. By maintaining consistent refrigeration and freezing conditions, cold chain management minimizes the risk of contamination and spoilage, safeguarding the health and well-being of consumers.

Furthermore, cold chain management plays a pivotal role in preserving the quality and freshness of perishable goods. Many food products, such as fruits, vegetables, seafood, and dairy products, are highly perishable and susceptible to degradation if not stored and transported under controlled conditions. Proper temperature control and monitoring throughout the cold chain help preserve the sensory attributes, nutritional value, and shelf life of these products, ensuring that they retain their taste, texture, and appearance until they reach the end consumer.

Moreover, cold chain management contributes to supply chain stability and efficiency. By maintaining the integrity of perishable products during storage and transportation, it minimizes product losses, reduces wastage, and enhances inventory management. This not only ensures a reliable and uninterrupted supply of fresh food to consumers but also optimizes the utilization of resources and minimizes economic losses for food producers, distributors, and retailers.

Cold chain management is indispensable for ensuring food safety, quality assurance, and supply chain resilience in the food industry. By meticulously controlling the temperature and conditions in which perishable goods are stored and transported, cold chain management protects consumer health, preserves product quality, and enhances the overall efficiency and reliability of the food supply chain.

Cold storage shelving plays a crucial role in cold chain management by providing efficient storage and display solutions for perishable goods within refrigerated environments. These shelving units are specifically designed to withstand low temperatures and maintain the integrity of food products while optimizing space utilization and facilitating inventory management.

First and foremost, cold storage shelving provides effective storage space for perishable items in refrigerated warehouses and cold rooms. These shelves are designed to withstand cold temperatures and are typically made of materials that are resistant to corrosion and moisture, ensuring durability and longevity in harsh environments. By maximizing vertical space and allowing for organized storage, cold storage shelving helps maximize storage capacity and optimize warehouse layout, enabling efficient utilization of available space.

In addition to storage, cold storage shelving also serves as a platform for displaying perishable goods in retail environments such as supermarkets, convenience stores, and specialty food shops. The ability to showcase products effectively enhances visibility and accessibility for customers, facilitating product selection and promoting sales. Moreover, organized and aesthetically pleasing displays contribute to a positive shopping experience and reinforce brand image and reputation.

Furthermore, cold storage shelving plays a critical role in maintaining food quality and safety throughout the cold chain. These shelving units are designed to facilitate proper air circulation and ventilation, ensuring uniform cooling and temperature distribution within the storage area. By preventing temperature fluctuations and maintaining consistent cold storage conditions, cold storage shelving helps preserve the freshness, flavor, and nutritional value of perishable foods, minimizing the risk of spoilage and foodborne illness.

Moreover, cold storage shelving facilitates efficient inventory management and stock rotation practices. With adjustable shelves and customizable configurations, these shelving units allow for easy organization and categorization of products based on type, size, and expiration date. This enables staff to quickly locate and retrieve items as needed, reducing handling time and streamlining operations. Additionally, clear labeling and signage further enhance inventory visibility and accuracy, facilitating inventory tracking and replenishment processes.

Cold storage shelving plays a multifaceted role in cold chain management by providing efficient storage and display solutions, maintaining food quality and safety, and optimizing inventory management practices. By ensuring proper storage conditions and facilitating organized and accessible product displays, cold storage shelving contributes to the overall effectiveness and reliability of the cold chain, ultimately benefiting both businesses and consumers.

Effective cold storage shelving is essential for maintaining the integrity of perishable goods in refrigerated environments and plays a critical role in cold chain management. Several key design elements and features contribute to the efficiency and reliability of these shelving units.

Firstly, material selection is crucial in ensuring the durability and functionality of cold storage shelving. Materials such as stainless steel, aluminum, and coated wire are commonly used due to their resistance to corrosion, moisture, and temperature extremes. These materials are also easy to clean and sanitize, making them suitable for food storage applications where hygiene is paramount. Additionally, insulated materials may be used to minimize heat transfer and maintain stable temperatures within the storage environment.

Secondly, the structural design of cold storage shelving is optimized to withstand low temperatures and heavy loads while maximizing storage capacity. Reinforced frames, sturdy shelves, and robust joints are essential features that ensure the stability and load-bearing capacity of the shelving units. Adjustable shelves allow for flexible storage configurations to accommodate products of varying sizes and shapes, optimizing space utilization and organization.

Temperature control is another critical aspect of cold storage shelving design. Integrated features such as airflow vents, perforated shelves, and open-grid designs facilitate proper air circulation and ventilation, ensuring uniform cooling and temperature distribution throughout the storage area. This helps prevent temperature differentials and minimize the risk of cold spots, which can compromise the quality and safety of stored goods. Some advanced shelving units may also include temperature monitoring and control systems to maintain precise temperature levels within the storage environment.

Furthermore, ergonomic design considerations are important for enhancing usability and efficiency in cold storage environments. Features such as smooth edges, rounded corners, and accessible handles contribute to ease of handling and reduce the risk of injuries or accidents. Clear labeling and signage systems help improve inventory visibility and facilitate quick identification of products, streamlining retrieval and stocking processes.

Effective cold storage shelving design incorporates a combination of durable materials, robust structural features, temperature control mechanisms, and ergonomic considerations to ensure the reliability and functionality of the shelving units in cold chain management. By providing secure and efficient storage solutions for perishable goods, these shelving units play a vital role in maintaining food quality, safety, and integrity throughout the cold chain.

Several successful case studies exemplify the effective application of cold storage shelving in various industries, showcasing their design concepts, practical outcomes, and contributions to cold chain management.

One notable example is a large-scale grocery chain that implemented customized cold storage shelving systems in its refrigerated warehouses. The shelving units were designed with adjustable shelves and modular configurations to accommodate a wide range of perishable products, including fruits, vegetables, dairy, and meat. The open-grid design allowed for optimal airflow and temperature distribution, ensuring consistent cooling throughout the storage area. As a result, the grocery chain was able to efficiently organize and store perishable goods while maintaining product quality and freshness. The customizable nature of the shelving systems also facilitated inventory management and stock rotation, contributing to reduced waste and improved inventory turnover.

Another successful case study involves a pharmaceutical company that upgraded its cold storage facilities with specialized shelving units designed for storing temperature-sensitive medications and vaccines. The shelving systems were equipped with temperature monitoring and control features, ensuring precise temperature regulation within the storage compartments. Additionally, the shelving units were designed with secure locking mechanisms and tamper-evident seals to prevent unauthorized access and safeguard the integrity of the stored pharmaceuticals. The implementation of these advanced shelving systems enhanced the company's ability to comply with regulatory requirements for storing pharmaceutical products and contributed to maintaining product efficacy and safety throughout the cold chain.

Furthermore, in the food service industry, a restaurant chain adopted customized cold storage shelving solutions to streamline its kitchen operations and ensure food safety compliance. The shelving units were designed with stainless steel construction and removable shelves for easy cleaning and sanitation. The shelving systems were strategically positioned in the restaurant's walk-in refrigerators and freezers to maximize storage capacity and accessibility. By organizing perishable ingredients and prepared foods on the shelving units, the restaurant chain was able to reduce food waste, minimize cross-contamination risks, and maintain strict temperature controls in accordance with food safety regulations.

These successful case studies demonstrate the critical role of customized cold storage shelving in enhancing cold chain management across various industries. By incorporating tailored design features, temperature control mechanisms, and ergonomic considerations, these shelving solutions contribute to optimizing storage efficiency, preserving product quality, and ensuring regulatory compliance in refrigerated environments.

Looking ahead, the future of cold storage shelving holds promising trends and advancements poised to revolutionize the industry. One significant trend is the continued emphasis on technological innovation to enhance efficiency and functionality. With the integration of IoT (Internet of Things) technology, cold storage shelving systems can become smarter and more interconnected, enabling real-time monitoring of temperature, humidity, and inventory levels. This connectivity allows for proactive maintenance and automated adjustments, ensuring optimal conditions for stored goods while minimizing energy consumption and operational costs.

Furthermore, the evolution towards intelligent design is expected to reshape the landscape of cold storage shelving. Advanced sensor technologies and AI (Artificial Intelligence) algorithms can analyze data patterns and predict storage requirements, facilitating dynamic shelving configurations and space utilization optimization. Additionally, ergonomic considerations and user-friendly interfaces will be prioritized to enhance ease of use and accessibility, empowering workers to efficiently manage inventory and streamline workflow processes.

Sustainability will also play a central role in the future development of cold storage shelving solutions. As environmental concerns continue to escalate, there will be a greater focus on eco-friendly materials, energy-efficient designs, and waste reduction strategies. Innovations such as recyclable materials, renewable energy sources, and modular construction techniques will contribute to reducing the carbon footprint of cold storage facilities while promoting eco-conscious practices throughout the supply chain.

Moreover, the integration of automation and robotics into cold storage operations holds immense potential for enhancing productivity and reliability. Automated retrieval systems, robotic picking technologies, and autonomous guided vehicles (AGVs) can streamline order fulfillment processes and minimize human error, leading to faster turnaround times and improved inventory accuracy. These advancements in automation will revolutionize cold storage logistics, paving the way for more efficient and cost-effective warehouse management practices.

The future of cold storage shelving is characterized by a convergence of technology, sustainability, and automation. By embracing innovation and adopting forward-thinking solutions, the industry can unlock new opportunities for improved efficiency, productivity, and environmental stewardship in cold chain management.

Allow me to introduce our factory, a leading manufacturer with 18 years of experience specializing in custom display shelving solutions. Over nearly two decades, we have honed our craft and established ourselves as industry experts in designing and manufacturing display shelving tailored to meet the unique needs of our clients.

One of the key strengths of our factory lies in our team of seasoned designers who possess a wealth of experience and creativity. With their expertise, they are adept at translating client requirements into innovative and functional display shelving solutions that effectively showcase products and enhance brand visibility.

Moreover, we take immense pride in the quality of our products. Each display shelving unit is meticulously crafted using premium materials and undergoes rigorous quality control measures to ensure durability, stability, and aesthetics. We understand the importance of presenting your products in the best possible light, and our commitment to quality craftsmanship reflects this dedication.

In addition to offering top-notch quality, we strive to provide competitive pricing without compromising on the excellence of our products. Our efficient production processes and strategic sourcing of materials enable us to offer cost-effective solutions, allowing our clients to maximize their investment in display shelving while staying within budget.

Furthermore, our commitment to customer satisfaction extends beyond the point of sale. We offer comprehensive aftersales support to address any inquiries, concerns, or maintenance needs that may arise post-purchase. Our responsive customer service team is always on hand to provide assistance and ensure that our clients' experience with our products remains positive and hassle-free.

In summary, our factory stands as a trusted partner in the realm of custom display shelving solutions. With our extensive experience, talented team of designers, commitment to quality, competitive pricing, and dedicated aftersales support, we are well-equipped to meet and exceed the expectations of our clients, delivering tailor-made solutions that drive success and elevate brand presence.

In conclusion, the efficient cold storage shelving system plays a vital role in cold chain management, serving as a crucial component in ensuring food safety and optimizing supply chain operations. By providing effective storage and display space for perishable goods within cold storage facilities, these shelving units contribute significantly to maintaining the integrity and freshness of food products throughout the entire supply chain process.

The ability of cold storage shelving to uphold proper temperature controls and storage conditions is paramount in preserving the quality and safety of perishable items, minimizing the risk of spoilage, contamination, and bacterial growth. This adherence to stringent temperature and hygiene standards not only safeguards consumer health but also enhances trust and confidence in food products, bolstering brand reputation and loyalty.

Moreover, cold storage shelving facilitates efficient inventory management and stock rotation, enabling businesses to effectively organize and access their inventory while minimizing waste and maximizing shelf life. This optimized supply chain management helps streamline operations, reduce costs, and improve overall productivity within the food industry.

In essence, the role of high-efficiency cold storage shelving cannot be overstated in the context of cold chain management. Its ability to uphold food safety standards, optimize supply chain logistics, and ensure product integrity underscores its indispensability in the preservation and distribution of perishable goods, ultimately contributing to a safer, more reliable, and more efficient food supply chain ecosystem.